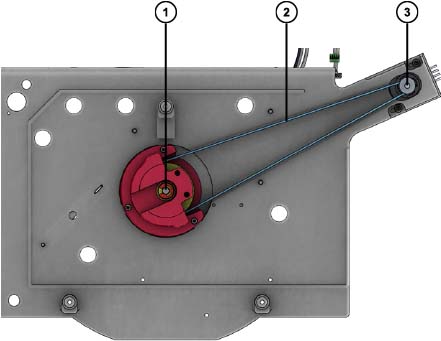

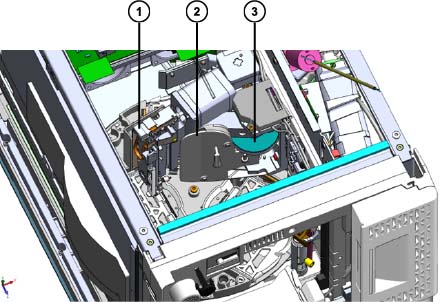

A dual-axes needle positioning mechanism draws the samples from the vials in the sample plates that the sample manager will inject onto a chromatographic column.

To line up the needle with the vials in the wells of the sample plates inside the sample compartment, the needle positioning mechanism’s two rotary axes control the orientation of the sample plates and the relative position of the sample needle carriage. Both rotary axes rotate a shaft using a belt and motor. The needle carriage rotates approximately 90° away from the inject port while the sample plates are on a continuous 360° rotary axis.

Need Help? Connect with a Waters expert.

To avoid risk of personal injury and to prevent damage to laboratory equipment, always operate your Waters products in accordance with the applicable operational and safety information, your organization’s standard operating procedures, and local regulations.

Refer to the English version of this page for the latest information.